Sustainability Projects

As a pioneering jeans development and manufacturing center, Denimvillage’s mission has been to raise the industry standards in sustainability from inception.

We believe sustainability is a continuous and credible act of commitment to long-lasting social and environmental justice through building and maintaining a corporate entire social responsibility system made of:

Today, we are driving the efforts to achieve a fully circular global fashion industry, and build new circular business models.

R&D PROJECTS

Known for our 20-year long innovative workshop-tradition, Denimvillage R&D Center has been the meeting point of some of the most well-known brands, fabric, chemical and machinery developers and countless global supply chain stakeholders.

- DOW XLATM Advanced Denim Collection

- Development of an indigo-dye replacement

- Applications for thermal-comfort and seamlessness

- No-water enzyme application for stone-wash effects

- Apricot seed and pineapple applications for wash effects

- Water-repellencethroughplasmatreatment

- Development of wrinklage machineR

- Dry-ice applications for wash effects

- Chemical applications for laser effect

- WaterLess-LessWaterCollections

- Aqua Project

- and many more…

CUSTOMER-SPECIFIC PROJECTS

We value co-creating with our strategic partners and supporting them through their sustainability journey. Based on their needs, we find or develop the right project.

We created separate vertically-integrated development and production lines inside our factories for circular and up-cycled products.

We research and find responsible solutions to re-create the value of all existing materials in the supply chain to operate within an end-to-end closed-loop circular ecosystem from raw material to delivery of the final product.

Our on-going projects include creating our partner-brands’ first up-cycled collections by turning post-industrial garments into new jeans and repurposing left-over dead-stock clippings and fabrics.

For more information, please contact us.

THE JEANS REDESIGN PROJECT

Laura Balmond, Make Fashion Circular Lead – Ellen MacArthur Foundation

In 2019, Denimvillage was invited to partner-up with Ellen Macarthur Foundation and join the Jeans Redesign Project as the first and only garment manufacturer from Turkey.

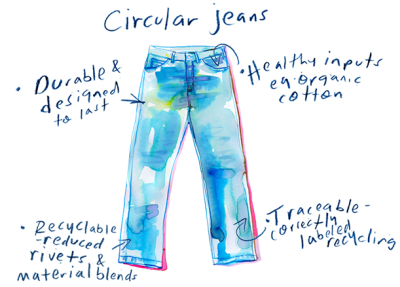

We invited Re/Done to this project as a partner-brand to make jeans based on these four main pillars of durability and longevity, material health, recyclability and traceability:

✓ Plastic-free with >%98 cellulosic content in textile composition

✓ GOTS-certified main fabric and pocketing (100% organic cotton)

✓ Pre- and / or post-consumer recycled content

✓ No sandblasting, no stone-wash, no electroplating

✓ Non-hazardous washing without potassium permanganate (PP)

✓ MRSL/ZDHC Level 1 compliant chemicals

✓ Use of Bluesigned-certified cold enzymes

✓ Coating-free / eco-coated metal accessories

✓ Easy-to-dissassemble / removable buttons

✓ Cruelty-free leather patch includes apple skin

✓ Clear wash instructions and symbols on care labels

✓ Hangtags made with 100% card board

✓ Internal barcoding for factory-level traceability

✓ QR Code for customer traceability

Liz Warren – sourcingjournal.com

read more